Find events

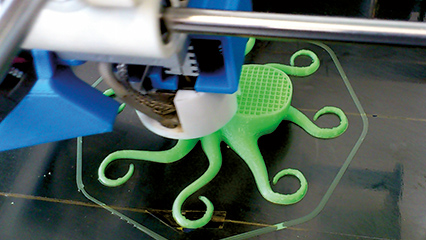

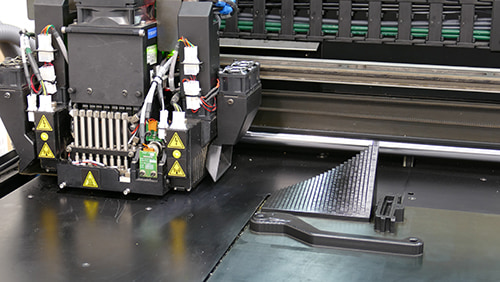

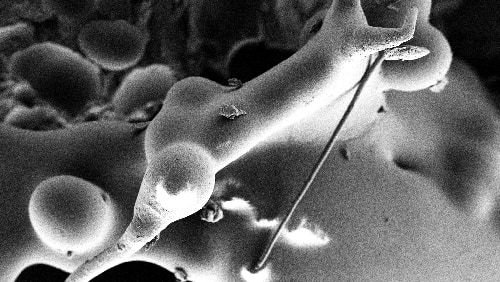

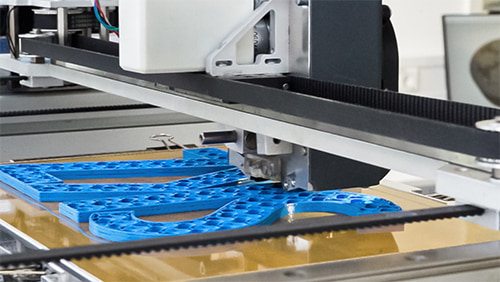

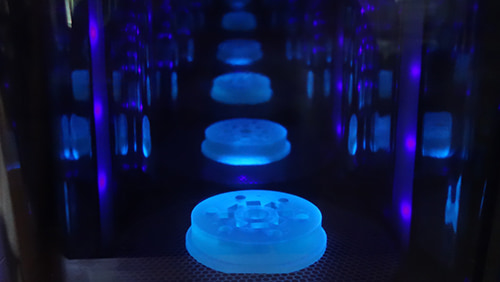

Additive Manufacturing

Stereolithography, fused deposition modeling, selective laser sintering, 3D printing - the range of additive manufacturing processes is broad. The industry is on the rise and the latest developments are presented every month. This makes it all the more important to stay up-to-date in this booming field. Shape the future of manufacturing with up-to-date knowledge and the practical skills you need. Our challenging courses for additive manufacturing offer you just the right basis for turning your product ideas into reality.

Currently our offer regarding standardized education courses in English is limited. If you cannot find the topic suiting your requirements you may look at our German website for courses additive manufactoring or simply contact us. A customized course meeting your requirements as in-house-training is always a possible solution.