Find projects

Blow molding and thermoforming

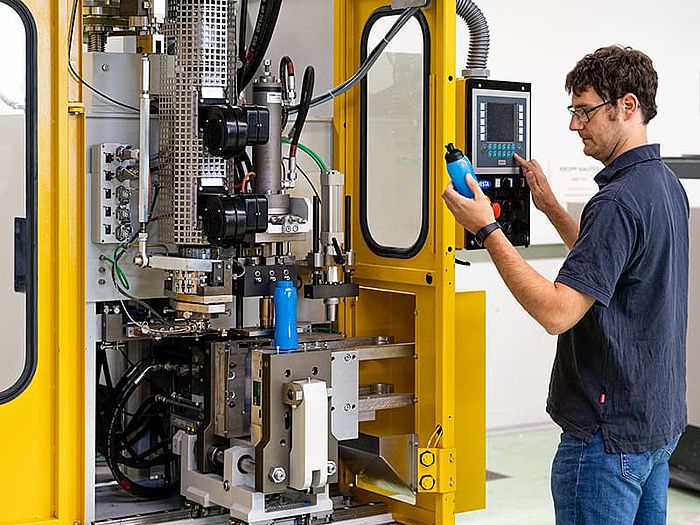

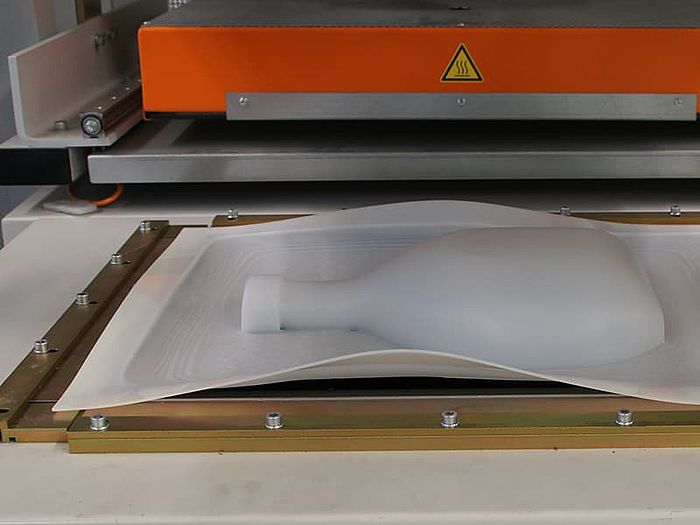

Thermoforming and blow molding are among the classic, discontinuous forming processes that have long been established in the plastics industry. In thermoforming, thermoplastic materials are formed under the influence of heat with the aid of compressed air or vacuum. This process is used to produce bathtubs, packaging and automotive components from films or thin sheets, for example. In contrast, blow molding is used to produce hollow bodies, such as bottles and tanks, which are blown from a plasticized plastic tube.

We deal very intensively with the machine technology and the challenging material properties of the plastics used. In particular, the degrees of forming and the resulting wall thicknesses are of great interest for the applications and sometimes require difficult machine and temperature settings. There is also a need for research into the orientation of fillers during processing by blow molding or thermoforming. The machines at SKZ are available to interested companies for sampling or material development at any time. Our experts support the projects with years of expertise. Our knowledge of thermoforming and blow molding is continuously expanded and passed on to companies in the context of advanced training courses.

Many plastics processing companies, just like SKZ, see great potential for innovation here, especially in the packaging sector. We will be happy to support you in your research and development as well as training and further education in this area.

Services

We sample tools on behalf of our customers, either customer-specific or according to SKZ procedures. We also offer the possibility of sampling thermoplastics and comparing their processability and properties. This also includes polymers that are still under development.

The production of semi-finished products for thermoforming, individually for the product to be developed, can be carried out directly in-house. SKZ has extensive equipment and the latest machines for compounding as well as for the extrusion of films and thin sheets.

Accompanying the thermoforming or blow molding processes, relevant material data such as rheological properties can be recorded and evaluated at the SKZ by means of HKR or Rheotens. The thermal properties of the materials, such as thermal conductivities and crystallization temperatures, can be determined at SKZ, as can mechanical product properties.

We develop customer- and product-specific materials for these discontinuous processing methods. In particular, the rheological material properties must be precisely adjusted and monitored for this purpose in order to obtain high-quality results and products.

The team consists of experienced engineers and technicians. During an on-site consultation, we can support you in process analysis and optimization as well as record almost all process-relevant and quality-determining measured variables in consultation.

With our experience in process measurement technology, SKZ is able to read out essential parameters from the machines, process them and control the processes accordingly. Innovative sensors, e.g. based on thermography or terahertz waves, are used for this purpose to facilitate operation and improve quality.

We develop the right process sequence for new products and new molds on a customer-specific basis. We can also draw on in-depth knowledge of wall thickness control. In blow molding and thermoforming, each material and each product to be manufactured requires its own product- and material-specific parameters, which must be developed and adapted in elaborate processes and test series.

As experts in the field of plastics technology, we strive to pass on the knowledge we have acquired over decades to our customers. From material development and manufacturing processes to the application of various testing and measuring methods - in our numerous practice-oriented training courses, you as a participant will acquire the necessary knowledge in dealing with plastics as a material. This begins with the selection of the right materials and compliance with production-oriented design rules, continues with the correct handling of equipment and machines for the manufacture and processing of plastic components and ends with the correct understanding of quality criteria and the associated use of testing and measuring tools.

Bringing together people from different areas of the company as well as from different industries to exchange experiences and technical know-how is also a top priority for us, in addition to the pure transfer of knowledge. Our numerous specialist events provide the ideal venue for a free exchange of ideas. Renowned speakers from a wide range of industries and excellent technical presentations make the SKZ conferences popular meeting places within the plastics industry.

State-of-the-art equipment for best results and products

A look inside our technical center. On more than 1,000 square meters, we offer you service at the highest level. Challenge us. Together we will find a solution for your problem.

Technical equipment

- HESTA HV 180

Travel: 180 mm

Opening travel: 140 - 110 mm

Closing force: 27 KN

Screw diameter: 36 mm

Hose head: PE/PP mandrel head

Manufacturer: HESTA

- Weber ZE45 single screw extruder

Barrier and three-zone screw

Calender and haul-off unit

Wide slot die for up to 350mm wide and 0.2 - 4.0 mm thick films or sheets

Manufacturer: Maschinenfabrik Weber

- Vacuum thermoforming machine Berg M5

Installation space 550 x 450 mm

Max. Material thickness 6 mm

Halogen heating unit, max. 399 C

Positive and negative molds available

Manufacturer: Berg