Find projects

Adhesive bonding

Adhesive bonding allows the same or different parts to be joined by means of an adhesive. This opens up many advantages compared to other joining processes such as welding or riveting. Parts to be joined are not mechanically weakened, forces are transmitted over a wide area, adhesives can conduct heat, insulate or dampen, and relatively free designs with flexible joints can be realized. For this reason, adhesive bonding has become accepted as the joining process of the 21st century across all industries in recent decades.

However, bonding is technically demanding and the design and production must be carried out professionally. We won't leave you out in the cold when it comes to bonding! In addition to our research in the field of adhesive bonding technology, we offer a wide range of services. Due to our industry-oriented approach, we are happy to provide you with advice and support tailored to the needs of your company and your bonding processes.

Service

Depending on the environmental conditions, changes occur in almost all bondings in the course of the service life. These can be seen, for example, in the reduction of the internal strength of the adhesive, the increase in brittleness, or the decrease in adhesion to the component material.

This can differ for each bond depending on the adhesive, processing and curing conditions, joining part material as well as production, surface treatment and stresses. It is therefore important to check the aging behavior on the original bond, if possible, in order to be able to determine reduction factors and design values for the stressability. For this purpose, we offer various accelerated aging tests for bonded joints, such as

- Climate change test (DIN EN 9142, PV1200, BMW PR 308.2, ...)

- Salt spray test (DIN EN ISO 9227, ...)

- Cataplasma test

- UV aging

- Immersion tests (media storage)

- Hot storage (constant climate test)

- Fatigue properties

Since adhesive bonding is one of those special processes where 100% non-destructive testing is not possible, bonded joints must be properly designed, tested and validated accordingly. For this purpose, not only the adhesive, but also the bonded parts as a complete system must be analyzed. At SKZ, a wide range of measuring and testing methods are available for characterizing the mechanical, thermal and rheological properties. In addition, support can also be provided for partial issues with inline testing methods for quality assurance.

Do you have an adhesive bonding problem? Are you looking for a practical solution to determine specific adhesive bonding process or quality parameters? We support you in the selection of adhesives for individual applications and manufacturing processes, search for suitable joining and testing methods, provide you with contacts and carry out preliminary investigations for suitability testing. Thanks to our trained staff and many years of experience and networking, we can respond to your individual requirements. This knowledge ranges from industrial methods to new technologies that are still in development or on the verge of first practical applications. We are also happy to support you in the initiation and implementation of funded projects for the further development and adaptation of your products to the needs of the adhesives and plastics processing industry. Please do not hesitate to contact us!

You want to use a new adhesive and want to test its suitability first? Are you carrying out a material change? We can investigate the practical and theoretical feasibility of adhesive bonding for you and help you integrate the adhesive bonding process into your process. For this purpose, we can injection mold test specimens with new materials in a wide variety of geometries (for example, tensile shear) and then bond test specimens. After mechanical testing, including evaluation of the fracture pattern and, if necessary, aging tests, we summarize the tests and results for you clearly in a report. In the feasibility studies, we thus test the suitability of adhesive systems according to customer requirements and specifications. You receive a statement on the suitability of the adhesive or substrate. We carry out these studies in close consultation with you, either in practical production processes or on the basis of theoretical considerations. This feasibility study provides you with the certainty that your investment is on target and will subsequently lead to an optimization of your bonding processes and thus to higher efficiency. In addition, we are happy to support you in initiating funded projects for the further development and adaptation of your products to the needs of the adhesives and plastics processing industry.

Are you looking for a new joining process for metals or plastic joints? Or a suitable surface pretreatment for a fast-curing 2K adhesive? Whether 1K or 2K, solvent-based or solvent-free adhesives... we will be happy to develop an individual adhesive system for you for special tasks. This includes the appropriate surface pretreatment method as well as substrate handling and adhesive selection. In doing so, we draw on our own development know-how and on existing solutions on the market and adapt them to your needs. The entire range of adhesive system development services we offer extends from the selection of optimum parameters for surface pretreatment to adhesive selection and suitable processing parameters. Non-destructive testing or process monitoring can already be taken into account at this stage. In close cooperation with you, we conceive, design, develop and manufacture bonded products for you as individual items up to small series.

Stress cracking, also known as environmental stress cracking (ESC), is a physical aging process in plastics caused by the simultaneous effects of external stress and internal stress. This can also be caused by liquid adhesives, primers, or pressure-sensitive adhesive tapes. The stress crack resistance of plastics to adhesives, primers, or cleaning agents is evaluated in accordance with DIN EN ISO 22088-3 using the flexural strip test.

Would you like to obtain information about your bondings that is not visible to the naked eye? SKZ offers the integration and, if necessary, individual adaptation of non-destructive inline measurement technology for process monitoring or as a laboratory testing method. In this way, for example, statements can be made about the curing progress of applied adhesives and bondings can be tested for application-specific quality characteristics. For example, it is possible to detect defects such as reduced adhesion, air and foreign material inclusions that lead to reduced mechanical properties.

For this purpose, SKZ offers a cost-neutral assessment of your testing task and enables comparative investigations with different methods based on ultrasound, terahertz, thermography and shearography, among others.

Contact:

Giovanni Schober | +49 931 4104-464 | g.schober@skz.de

As experts in the field of plastics technology, we strive to pass on the knowledge we have acquired over decades to our customers. From material development and manufacturing processes to the application of various testing and measuring methods - in our numerous practice-oriented training courses, you as a participant will acquire the necessary knowledge in dealing with plastics as a material. This begins with the selection of the right materials and compliance with production-oriented design rules, continues with the correct handling of equipment and machines for the manufacture and processing of plastic components and ends with the correct understanding of quality criteria and the associated use of testing and measuring tools.

Bringing together people from different areas of the company as well as from different industries to exchange experiences and technical know-how is also a top priority for us, in addition to the pure transfer of knowledge. Our numerous specialist events provide the ideal venue for a free exchange of ideas. Renowned speakers from a wide range of industries and excellent technical presentations make the SKZ conferences popular meeting places within the plastics industry.

State-of-the-art equipment for best results and products

A look into our technical center. We offer you services at the highest level, challenge us! Together we will find a solution for your problem as well

Technical equipment

For the mechanical, physical and chemical pretreatment of plastic surfaces an automated pretreatment stand and the following equipment are available for test series.

- Low pressure plasma (various gases and precursors possible)

- Atmospheric pressure plasma (rotating and static nozzles)

- Atmospheric pressure plasma coating cell

- Corona (direct and indirect)

- Cold active plasma

- Flame treatment

- VUV emitter

- UV laser

- CO2 laser

- Primer

For the production of specimens for mechanical tests or for the preparation of specimens for optical analyses, the following devices and equipment are available.

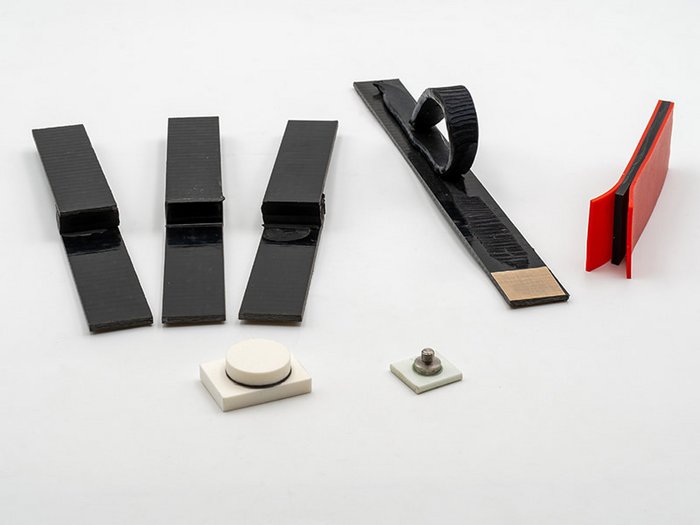

- Adhesive fixtures (e.g. tensile shear test specimens with variable adhesive layer thickness adjustment, three-point bend test specimens, peel test specimens, etc.)

- UV curing oven and heating ovens

- Vacuum embedding system

- Precision separators

- Grinding and polishing equipment

- Precision syringe dosing system

- Peristaltic hose pump

- Pressure time dosing system

- Cartridge presses different mixing ratios and volumes (manual, pneumatic, electric)

- Pneumatic hot spray system

- Mechanical test methods

- Determination of tensile strength according to DIN EN ISO 527

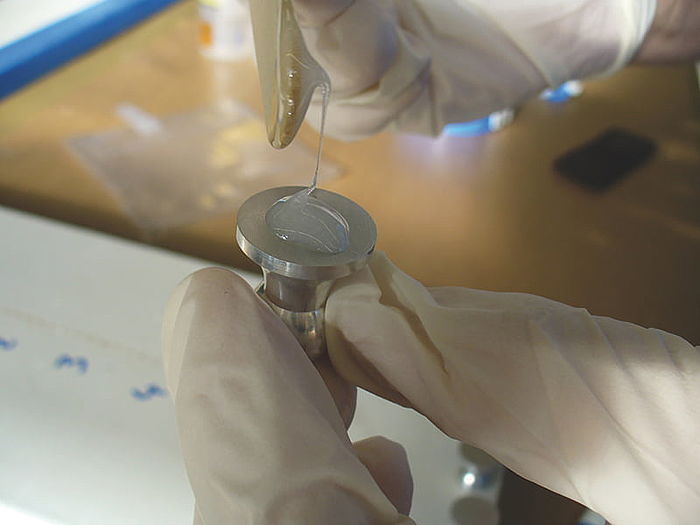

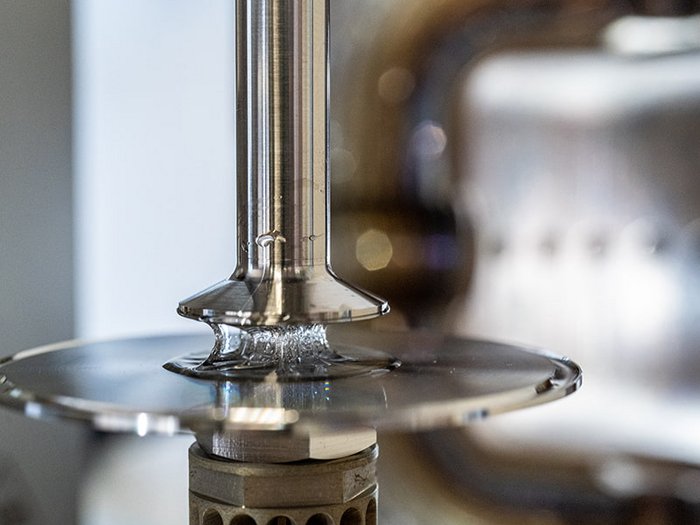

- Determination of the tensile strength of butt splices using Centrifugal Adhesion Testing technology (CAT technology) according to DIN EN 15870 with LUMiFrac

- Tensile shear testing (tensile shear strength) according to DIN EN 1465

- Three-point bending test according to DIN EN ISO 178

- Peel test (roller peel strength) based on VDI 2019 and DIN EN 1464

- Inline quality assurance

- Infrared cameras for monitoring reactive adhesive curing as well as surface pretreatment

- High-speed camera systems

- Terahertz (THz) and unilateral nuclear magnetic resonance (NMR) for monitoring adhesive curing processes

- Microscopy and chemical surface analysis

- Reflected and transmitted light microscopes

- X-ray photoelectron spectroscopy (XPS/ESCA)

- Molecular spectroscopy (FT-IR, Raman)

- Electron microscopy (SEM-EDX/ESEM)

- Atomic force microscopy (AFM)

- Thermophysical analysis

- Calorimetric analysis (DSC) for the determination of reaction and hardness profiles as well as glass transition temperatures

- Heating stage microscope for visual evaluation of transformation and reaction processes (temperature range from -196 to 600 °C)

- Thermogravimetry (TG) for determining decomposition points and filler contents

- Temperature and thermal conductivity measurements

- Thermomechanical analysis (TMA) for determination of the coefficient of linear thermal expansion

- Dynamic mechanical analysis (DMA) to investigate viscoelastic material behavior: glass transition temperature, Young's modulus, storage modulus, loss modulus.

- Rheometer to evaluate the rheological processing properties of polymer melts,

- Climate change test (DIN EN 9142, PV1200, BMW PR 308.2, ...)

- Salt spray test (DIN EN ISO 9227, ...)

- Cataplasma test (DIN EN ISO 9142; Annex E2)

- UV aging (DIN EN ISO 4892-1, -2, -3)

- Immersion tests (media storage, DIN EN ISO 175)

- Hot storage (constant climate test)

- Fatigue properties

3 questions - 3 answers about bonding plastics

Selecting the right adhesive for a specific application is not trivial. The first step is to draw up a requirements profile for the adhesive. This should include the materials to be joined, application conditions, mechanical stresses and resistance to external influences, in order to provide a brief insight. Based on the requirements profile, adhesive classes can then be selected and specific adhesives researched. We support you in the creation of requirement profiles and in adhesive research!

If a failure occurs in a bonded joint, there are various possible causes. Often, the failure of the bond is due to user error. First of all, it is advisable to take a closer look at the fracture pattern and localize the damage. Does the failure occur mainly in the adhesive, in the joined part or in the interface? How was the component loaded and what aging effects and external influences have taken place? Depending on the fracture pattern, targeted measures can thus be derived. We will be happy to support you with your problems!

In real bonded joints, it is not just individual mechanical stresses that occur, but a smorgasbord of stresses and external influences. These include humidity and temperature, radiation, liquids (media), microorganisms and many more. This can lead to a reduction in the internal strength of the adhesive, an increase in brittleness, or a decrease in adhesion to the joining part material. Therefore, it is important to use accelerated or time-rapid aging tests to check the aging behavior on the original bond, if possible, and to take it into account in the design.

5 fundamentals of adhesive bonding

1. Adhesive selection

Using the right adhesive for specific plastics is extremely important. Not all adhesives are suitable for all types of plastic. When selecting an adhesive, the joining partners, environmental conditions, environmental influences, tolerances, aging, load transfer, and other functions and influences must be taken into account. We are happy to provide you with systematic support in selecting the right adhesive.

2. Surface preparation and treatment

The surfaces to be bonded must be clean, dry, and free of grease. Residues such as dust, oil, or lubricants can impair the adhesion of the adhesive. The more thorough the surface preparation, the stronger and more durable the adhesive bond will be. If necessary, surface pretreatment or activation is required to achieve optimum performance in terms of adhesion and long-term stability. In addition to primers as bonding agents, physical processes such as plasma or irradiation are also possible.

3. Adhesive application

When applying adhesives, a distinction is made between manual and automated processes. The application equipment and throughput vary accordingly. In both processes, the correct amount of adhesive, its distribution, and complete filling of the bonding surface after joining are important. Non-destructive measurement technology is often used to monitor adhesive application, especially in automated processes.

4. Fixing and hardening

After joining, it is important to secure the bonded components until they are strong enough to be handled. In addition, the chemistry of the respective adhesives and their chemical reactions must be taken into account for curing. This may include necessary moisture, elevated temperatures, or radiation activation. Manufacturer's specifications regarding curing time and environmental conditions must always be observed.

5. Testing and aging

The performance of adhesives must be tested, particularly in development projects but also during production. In addition to static tests immediately after curing, various application-related load scenarios and aging effects must also be taken into account. In the case of plastics, stress cracking caused by primers or adhesives must also be explicitly considered.