Find projects

WPC - Wood Polymer Composites

The use of renewable raw materials in the plastics industry is becoming increasingly important. SKZ has been accompanying the development of new WPC materials or natural fiber reinforced plastics (NFK) since 2003. We deal with the individual steps of the entire value chain (excluding synthesis) of these materials, starting with formulation development and ending with recycling. Our activities focus on material selection and formulation optimization as well as on the technologies most relevant for WPC and LFPs: compounding, extrusion, injection molding, welding and bonding. In addition, our services are complemented by sustainability assessment and quality assurance.

Services

Together with the experts for compounding and injection molding, we can turn your ideas into real products. We are happy to advise them on the optimum process control and supply them with test specimens for further characterization. Together with them, we further develop the new formulations up to series production.

Thanks to our many years of experience, we can provide you with application-specific formulations. The selection of suitable base materials, additives and functional fillers or reinforcing materials provides the basis for high-performance WPC compounds.

SKZ can look back on many years of experience with regard to the processing of WPC formulations and, depending on the requirements profile, can advise them on the optimization of extrusion technology and the selection of the right process parameters.

Among others, we test according to the following already existing regulations:

- Tests according to the quality and testing regulations of the Qualitätsgemeinschaft Holzwerkstoffe e. V. (Quality Association for Wood Materials)

for obtaining the quality seal for decking (initial test and external monitoring) - Tests according to DIN EN 15534

- Tests according to ÖNorm B3031; ÖNorm B3032

- Preparation and execution of test programs for building authority approvals for statically relevant applications

The tests include:

- Tests of material properties:

e.g. mechanical and thermal properties, resistance tests - Tests of product properties:

e. g. water absorption, bending behavior, impact resistance, long-term behavior, slip resistance, chemical resistance, weathering resistance, temperature behavior

Are you looking for thermal or adhesive joining techniques to join your materials with a high quality? You want to pre-treat or analyze the surface of your plastic components? SKZ supports you in the selection of mechanical or physical surface pretreatment as well as joining processes according to technical and economic criteria also at your site.

To the areas of welding | bonding | surface technology

Are you considering using WPC for your products or are you thinking about improving the property profile of your formulation? Then contact us! We will be happy to support you with our wide range of knowledge in the implementation of innovative and economically attractive solutions.

For WPC products, which so far are mainly found in outdoor applications, high long-term stabilities of up to 25 years are required. Therefore, testing the long-term stability and predicting the service life for WPC in outdoor applications are particularly important. Taking into account the factors of moisture, radiation, temperature and the presence of microorganisms, we have developed test methods for predicting biological resistance in cooperation with the University of Göttingen. We would be happy to support you with our expertise.

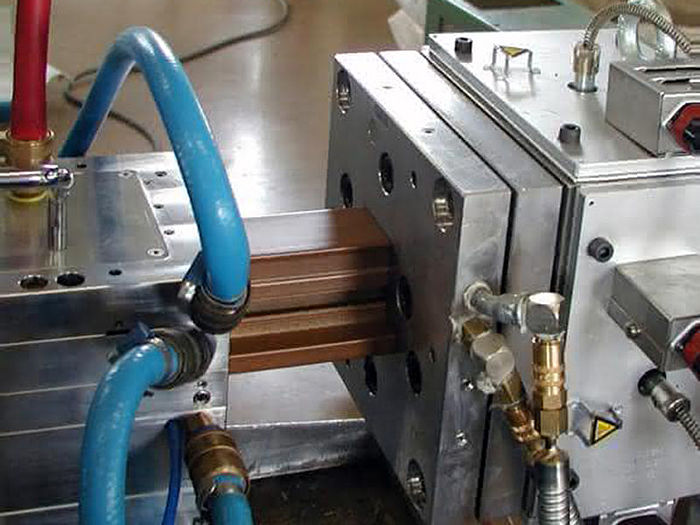

The processing of WPC by means of injection molding poses high challenges for processors. During injection molding of WPC materials with filler contents above 40 wt.%, problems frequently occur, such as the formation of flow anomalies or segregation during the filling process. These phenomena significantly impair component quality and also make it difficult to predict the molded part filling and the resulting component properties. In addition, the occurrence of high shear stress during processing can cause thermal damage to the wood fibers, which reduces component quality. Please feel free to contact us if we can assist you with any questions that may arise.

Along the entire value chain of WPC components, non-destructive measurement and testing methods provide decisive parameters for optimizing manufacturing processes, shortening product development cycles and assessing the final component quality. This includes the determination of fiber volume content and fiber orientation as well as the detection of manufacturing and application-related defects such as voids and cracks. For this purpose, various laboratory and inline testing methods based on ultrasound, X-ray including computer tomography, thermography, terahertz and radar technology are available at the SKZ.

State-of-the-art equipment for best results and products

In our state-of-the-art laboratories, we conduct research into the materials of tomorrow. We work closely with industry to make many good products even better and, above all, more sustainable. Challenge us. Together we will find a solution to your problem.