Search standard for testing available at SKZ

In our testing laboratory in Würzburg we carry out a wide range of standardized tests for automotive components and support you in the release of plastic materials and assemblies for the automotive industry.

In our testing laboratory in Würzburg we carry out a wide range of standardized tests for automotive components and support you in the release of plastic materials and assemblies for the automotive industry.

Your specialists for testing plastic components for the automotive industry

We are partners of the automotive manufacturers and their suppliers

Beyond the requirements of DIN EN ISO/IEC 17025 or VDA 250, many automotive manufacturers have developed their own criteria for test laboratories regarding automotive release testing. Based on accreditation according to DIN EN ISO/IEC 17025, testing laboratories are approved or recommended by OEMs for certain procedures.

We look at all material requirements from the ground up and support you in meeting the standards of the automotive manufacturers. Our many years of experience in testing plastic parts and our comprehensive range of tests in the field of automotive testing will help you find the best solutions and meet the highest requirements.

Contact us, we will be happy to help you!

Selected test methods for automotive components

- Firing test

- Chemical resistance

- Color measurement

- Gloss measurement

- Odour measurement

- Climate change test

- Material identification

- Mechanical tests

- Salt spray test

- Thermal test

- UV and weathering resistance

- UV-C resistance test

Further information about our test methods

BMW approval according to GS 93016

Test laboratory approved by the BMW Group

Due to the continuous update of the group standard 93016 for plastics and thermoplastics at the BMW Group, the inclusion of material trade names and material certification is newly regulated. In addition to a wide range of practical and theoretical requirements, a release test by a BMW-approved laboratory is mandatory for raw material manufacturers and for materials. The type and number of tests have been defined by the BMW Materials Development Department.

To date, five laboratories worldwide have been approved by the BMW Group to perform these tests. Among them are the testing and laboratory facilities of the SKZ in Würzburg. Here, quality testing and quality assurance have been successfully carried out for decades. The acceptance as an official testing laboratory by the BMW Group is both an award and an incentive for the engineers and scientists at SKZ.

10 steps to successful testing according to GS 93016

In order to carry out the listing process we need information about the type and number of materials to be approved for the BMW Group.

We ask for the following information

- The number of semi-crystalline materials: Do the objects contain PA?

- The number of amorphous materials: Do the objects contain ABS?

To enable us to start the process implementation quickly, please send us the test program required by the BMW Group for your listing.

For transmitting the processing guidelines of the materials or all other documents please send us an e-mail

We look forward to receiving your documents and will be happy to prepare your individual offer after reviewing them.

We look forward to receiving your order and at the same time assure you of prompt and professional processing.

Subsequently, you provide us with the granulate(s) for testing.

The production of the test specimens is part of the test program and is carried out by us.

Now the actual analytical and mechanical tests for listing in GS 93016 begin.

The SKZ prepares a test report with the required material characteristics.

In addition, we will send you the results report and the laboratory protocols in order to submit the application for release of the tested material to BMW.

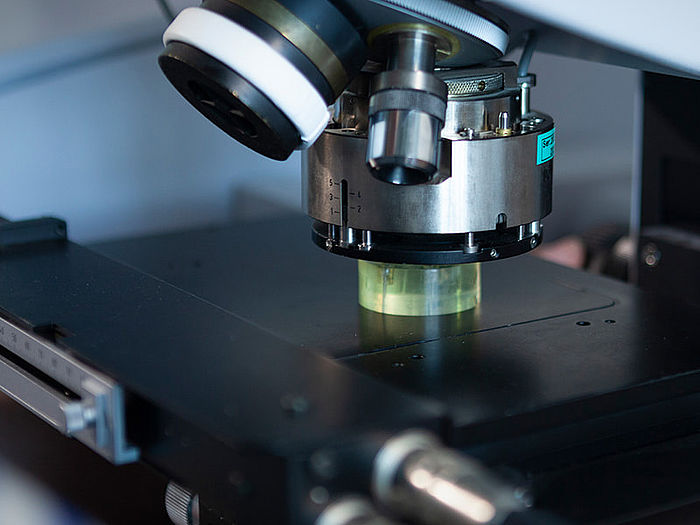

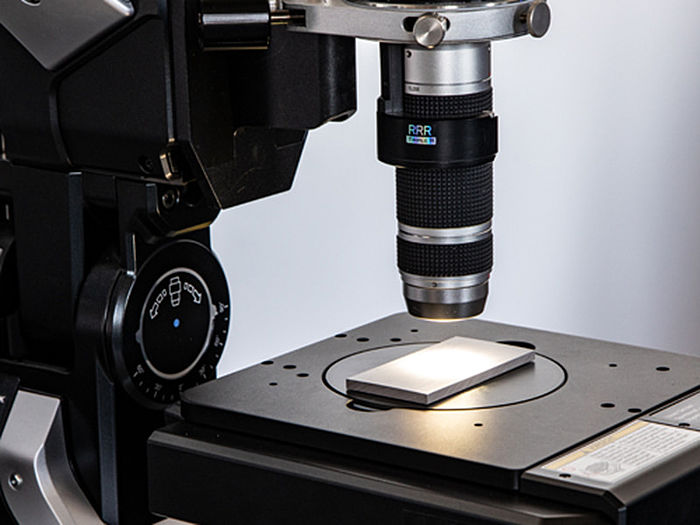

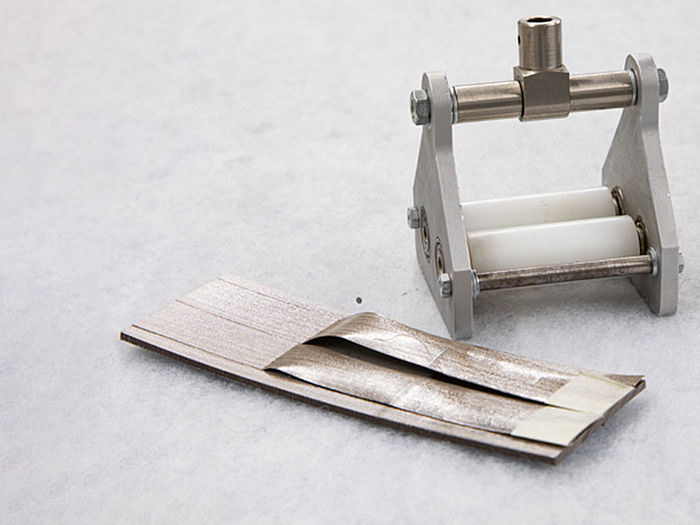

State-of-the-art equipment for best results and products

In our various laboratories and test rooms, we have a wide range of testing equipment for different test procedures.