Find projects

PVC - Polyvinylchlorid

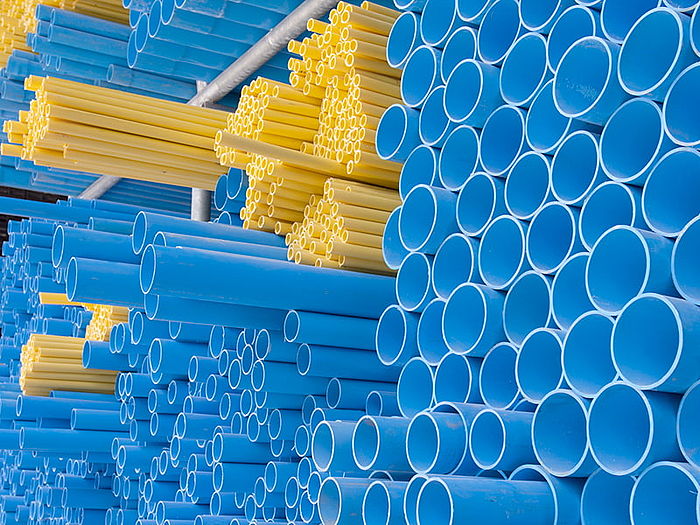

Whether as flooring, as window profiles, as plastic pipes or children's toys: PVC is characterized by its very high bandwidth of the most diverse applications. This is due not least to its outstanding chemical and physical properties, such as good stability against sunlight, difficult inherent flammability and good chemical resistance. PVC is one of the oldest polymeric materials, having developed into one of the most important and inexpensive mass-produced plastics from its first large-scale production in the 1920s to the present day. It owes this primarily to constant further development both in the field of polymer synthesis and in the additivation and research of new and customized formulations. With our many years of experience in the development of formulations and the processing of PVC, we are the perfect partner for you when it comes to equipping this material for future challenges. For this purpose, SKZ has decades of know-how and an extensive machine park for PVC processing and testing, which we are happy to share with you.

Services

In the preparation phase, the additives used are incorporated into the PVC matrix with a mixer. During this process, the powder heats up due to the friction of the material or the collision of the particles, so that the temperature rises continuously. The challenge is to distribute the additives homogeneously by adjusting the process parameters (speed, temperature and time) without overloading the PVC. In this phase, the PVC grain absorbs liquid additives, so that a dry, free-flowing powder, the so-called dry blend, is formed again. This can be further processed into molded parts or granules, e.g. with an extruder, without any further processing step.

The following mixers are available at SKZ for the preparation of PVC dry blends:

- Heating/cooling mixers of type FML10 - KM23, company: Zeppelin Reimelt, Kassel, Germany

- Container mixer of type CM 80-H, company: Mixaco, Neuenrade

As one of only a few institutes in Germany, SKZ offers complete support in the development of PVC products. For this purpose, our many years of know-how as well as numerous facilities for the compilation of formulations, preparation and processing of dry blends, and characterization of materials and components are available to you. In order for your product to develop its full performance potential, the material selection, processing and component design must be optimally coordinated. Together with our colleagues, we will be happy to advise you along the entire process chain.

In our pilot plants, we have the most modern equipment available for small-scale and laboratory production. We also offer a wide range of special processes. Please feel free to contact us at any time.

Do you need innovative solutions to implement your ideas? Our experts will be happy to support you here and research alternative materials or the use of recyclates for you. Together with you, we create a requirements profile for your product and research suitable materials in databases of manufacturers, organizations and research institutions.

After polymerization, PVC cannot be processed without further modification. To process PVC, it is mixed with suitable additives, especially stabilizers, but also with fillers, plasticizers, lubricants, pigments or impact modifiers. Typical applications are gutters, window profiles, pipes, films, cables or various seals. SKZ provides support in the development of new or optimization of existing formulations with regard to the desired properties.

The various application-specific parameters that can be measured and inspected non-destructively are as diverse as the possible applications of PVC. Geometry determination on a micrometer to decimeter scale as well as the characterization of formulations and the detection of defects in products can be carried out using a wide range of non-destructive methods. For this purpose, extensive measurement technology is available for laboratory and inline use based on ultrasound, X-ray including computer tomography, thermography, terahertz and radar technology, among others.

State-of-the-art equipment for best results and products

In our state-of-the-art laboratories, we conduct research into the materials of tomorrow. We work closely with industry to make many good products even better and, above all, more sustainable. Challenge us. Together we will find a solution to your problem.

Technical equipment

In order to be able to manufacture a competitive PVC product, the selection of the suitable processing method, the right machine as well as the optimum process parameters is a prerequisite. Depending on the type of end product and its quality requirements, a wide range of processes for PVC processing on an industrial scale can be offered at SKZ. For the production of pressed sheets, extruded profiles, films, pipes, or even injection-molded PVC samples, the SKZ's processing technology center has a large number of process-standard machines for processing PVC:

- Press type P 300 P from COLLIN Lab & Pilot Solutions GmbH

- Laboratory kneader of the type Plasticorder PL200 from Brabender

- Polystat 110 rolling mill made by Schwabenthan

- ZE45 single-screw extruder made by Maschinenfabrik Weber

- Counter-rotating twin-screw extruders of type DS 7.22 made by Maschinenfabrik Weber

- Counter-rotating twin-screw extruders type CE3 made by Maschinenfabrik Weber

- TP-WE 70/800 M2 planetary roller extruder from Entex, Bochum, Germany

- Twin screw extruder type Teach-Line ZK25T from COLLIN Lab & Pilot Solutions GmbH

- Various extrusion tools (profile tools, film dies, pipe heads)

- Various injection molding machines

Analytics in the field of PVC materials and components

- Tensile properties according to DIN EN ISO 527 or ASTM D638

- Charpy impact strength according to DIN EN ISO 179

- Hardness according to DIN EN ISO 868 or ASTM D2240

- Dynamic mechanical analysis (DMA)

- Creep and creep rupture

- Fatigue / endurance test

- Gel permeation chromatography (GPC): The determination of molar mass distribution and polydispersity allows conclusions to be drawn about polymer degradation due to aging.

- Gas chromatography with mass spectrometry coupling (GC/MS): The method allows the qualitative and quantitative determination of readily volatilizable polymer components (VOC). Possible areas of application are the determination of direct emissions from the plastic, e.g. relevant in automotive interiors; and the detection of highly volatile degradation products or contaminants in the component, e.g. relevant for food packaging or toys.

- High-pressure capillary rheometer (HKR) from the Göttfert company: A high-pressure capillary rheometer can be used to measure viscosities and shear stresses as a function of shear rate and temperature. The data obtained in this way can then be described by material models such as the Carreau approach and serve, for example, as input variables for simulation calculations of injection molding and extrusion processes. In addition, comparative studies can also be used to make statements about material degradation.

- Melt flow rate (MFR) tester from Göttfert: can be used to determine the melt flow rate MFR in g/10min or the volume flow rate MVR in cm³/10min of plastic granules and powders.

- Elongation tester (Rheotens): with an elongation tester (Rheotens) coupled to the HKR, the effective elongation viscosity can be determined reproducibly. Possible applications: Film extrusion and blow molding

- Dynamic thermostability (Kneader measurements)

- Plasticizing time (kneader measurements)

- Static thermostability (DHC according to DIN EN ISO 53 381)

- Vicat softening point according to DIN EN ISO 306

- Heat deflection temperature (HDT) according to DIN EN ISO 75

- Temperature and thermal conductivity according to DIN EN ISO 22007-4

- Particle size distribution: dynamic image analysis or laser diffraction (camsizer, mastersizer), as well as sieve analyses

- Density determination: by means of buoyancy methods or liquid pycnometer

- Bulk density

- Flowability

- Filler content: by ashing

- Microscopic analyses: SEM/EDX (scanning electron microscopy with energy dispersive X-ray spectroscopy),

polarization, light and heating microscopic analyses