Trust is good, control is better: measurable monitoring of adhesives

At the SKZ Plastics Centre, terahertz (THz) and radar technology are used to determine the curing progress of applied adhesives. This enables companies to shorten production processes and avoid faulty bonding. Not only does this offer time and financial advantages, it also enables modern quality control.

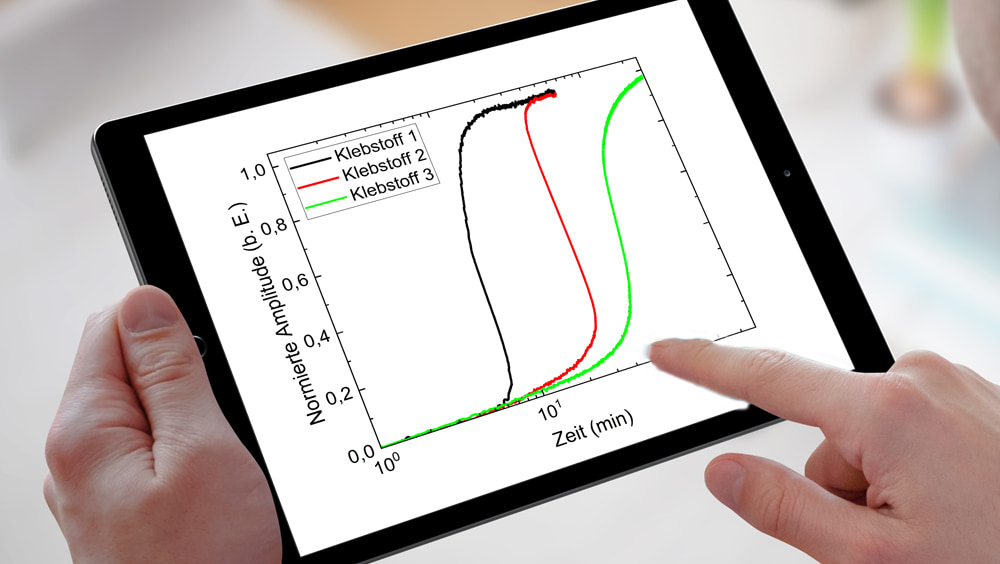

Measurement of the curing progress of three different adhesives using THz technology. (Source: SKZ)

With innovative measurement technology, SKZ enables real-time monitoring of curing processes for the first time – without any access to the bonding site.

Adhesives are used in almost every industry to bond different types of materials. Bonding has become an essential component, particularly in lightweight construction and the automotive industry. Since the components are often difficult to access after bonding, no quality assurance measures can be used to monitor the bonding progress. The only option is therefore to blindly trust the adhesive manufacturer's specifications and adhere to certain characteristic curing times, which are subject to tolerance times. However, the curing of adhesives depends on environmental conditions such as temperature and humidity and can therefore be completed prematurely or later than expected.

The SKZ, a member of the ZUSE community, addressed this existing problem in a completed research project and came to the conclusion that both THz and radar technology are capable of determining the curing progress of adhesives that are no longer accessible – both non-destructively and without contact. This is possible because the electromagnetic waves of the measurement methods interact with the polymer chains of the adhesives and behave differently depending on the polymer chain length, which changes during curing. Accordingly, the attenuation of the measurement signals can be used to make a valid statement about the existing curing progress. This enables precise determination of the time for the transition of the bonded component to the next production step and, if necessary, the specification of an additional curing time.

Since both measurement techniques do not require radiation protection and are also flexible in their application, they can be easily used in existing production facilities to monitor the process. SKZ is happy to support companies in integrating the measurement technology into their production facilities. If you are interested in improving your quality control and also want to save time and money, please do not hesitate to contact us.