New validation method for laser-sintered PP components

The RaPPoD research project aims to enable the validation of previously undemonstrated component properties for laser-sintered PP parts by developing a suitable PP powder and laser sintering monolayers.

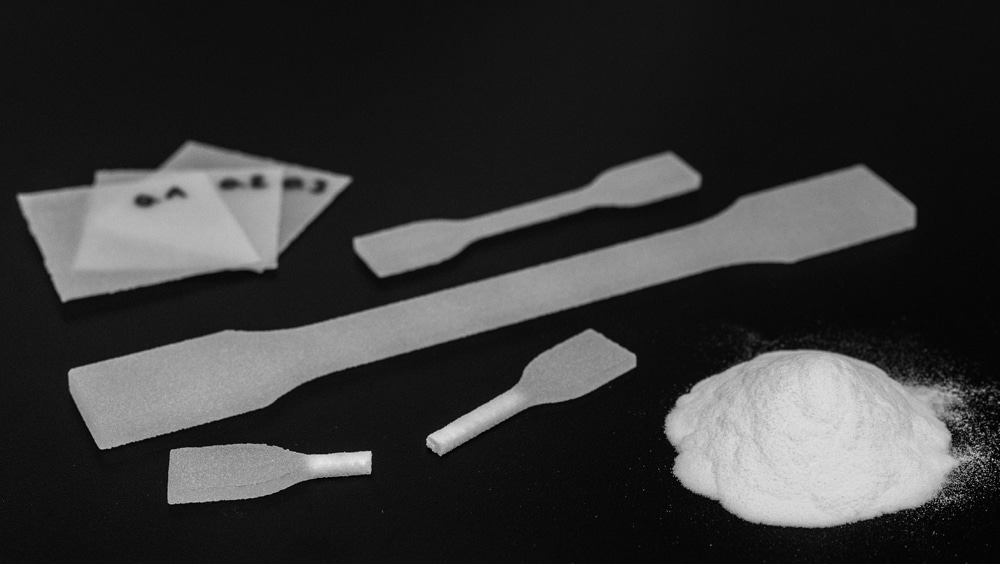

Printed monolayers (plates) to be used in the project as a rapid process establishment method, tensile bars for validation, and a sample of the PP powder used, Rolaserit PP01 from AM Polymers. (Photo: Luca Hoffmannbeck, SKZ)

The RaPPoD – Rapid PBF Polymer Development project marks the launch of a pioneering initiative aimed at accelerating the development of novel plastic powders for additive manufacturing using powder bed fusion (PBF), also known as selective laser sintering (SLS). The aim is to establish an innovative validation method based on the printing of so-called monolayers, which significantly accelerates the development process for new materials and makes it more resource-efficient.

Additive manufacturing processes have long since evolved from prototype production to industrial series production. The PBF process in particular is considered one of the most efficient methods for manufacturing complex plastic components. Currently, however, the market is dominated by a single material – polyamide 12. This significantly limits the variety of component properties and fields of application.

This is where RaPPoD comes in: instead of analysing complex tension rods as has been the case up to now, the project is developing a novel method for powder evaluation using thin, single-layer samples (monolayers). These require only minimal amounts of powder and enable a fast, cost-effective and yet meaningful evaluation of new materials.

Specially developed key figures combine material data, process parameters and monolayer properties to identify promising material-process combinations at an early stage. Initial laboratory tests with established polymers such as PA 12 and PA 11 already demonstrate the potential of this approach.

The service provider and project partner VISIOTECH GmbH already has a wealth of experience in developing parameters in the SLS process for various plastics, such as PA 613 and PA 12 in black, which VISIOTECH successfully uses for the market in machine and housing construction as well as in the automotive sector.

The aim is now to jointly develop and test new PP powders, including additivated powders. The goal is to expand the range of materials available for the PBF process and thus open up new applications.

The project offers industrial partners the opportunity to acquire expertise in the development or processing of novel PBF powders at an early stage – a clear competitive advantage in a market with annual growth rates of around 18%.

RaPPoD represents an important step towards sustainable, efficient and versatile additive manufacturing.

This project is funded by the Central Innovation Programme for SMEs (ZIM) with the funding code KK5068076BU4 from 1 June 2025 to 31 November 2027 by the project management agency AiF Projekt GmbH and the Federal Ministry for Economic Affairs and Climate Protection (BMWK).