Cleaning process added at SKZ: CO₂ snow blasting for plastic surfaces

The SKZ Plastics Center has commissioned a modern CO₂ snow blasting system. The system enables dry, residue-free cleaning of plastic surfaces and strengthens both current research projects and the range of services offered to industry.

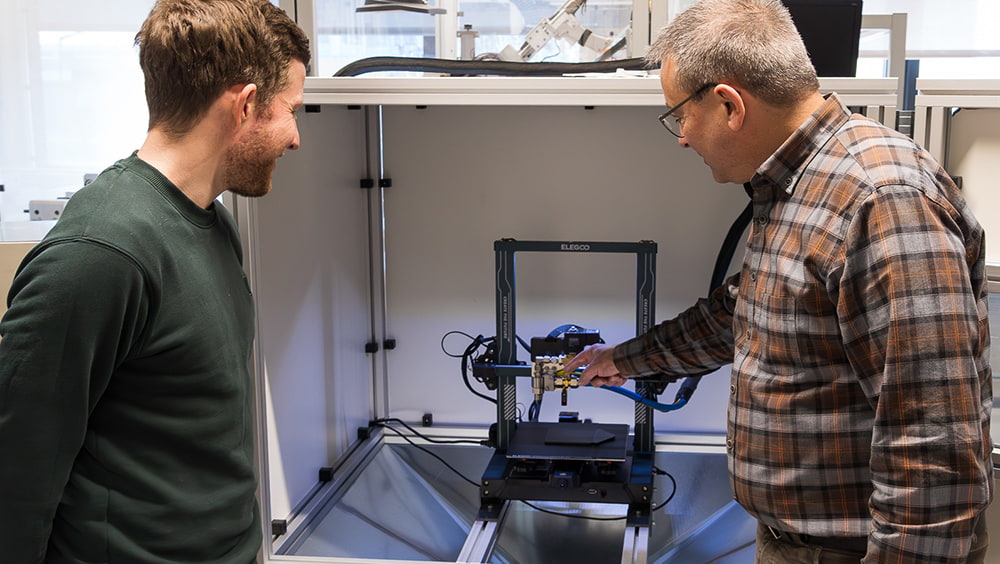

During commissioning of the JetWorker P16 CO₂ snow jet cleaning device at SKZ, Peter Eggert (Sales & Technology Expert at acp systems AG, right) explains how the system works to David Herbig (scientist at SKZ). (Photo: Luca Hoffmannbeck, SKZ)

New equipment available for research projects and industrial services

SKZ has expanded its technical infrastructure with a JetWorker P16 CO₂ snow blasting machine from acp systems AG. The system is based on quattroClean® technology and will be used in future research projects on surface cleaning and pretreatment, in particular to investigate how recycled surfaces can be specifically optimized using CO₂ snow.

“With the new industrial-grade snow blasting system, we are opening up an environmentally friendly and highly effective process for our research work,” explains David Herbig, scientist in the Adhesives and Surface Technology group at SKZ. “At the same time, we can provide even better support to our customers in the plastics industry with demanding cleaning tasks. Process parameters can be transferred directly to the industrial environment.”

The process combines compressed air and CO₂ snow to clean surfaces dry, chemical-free, and without leaving any residue. Particles, fibers, and film-like contaminants can be removed quickly and reproducibly without downstream drying or waste materials. The separate control of compressed air and CO₂ flow allows the cleaning intensity to be precisely adjusted to the respective material.

“CO₂ snow blasting offers enormous potential, especially for plastic applications, as it protects surfaces while ensuring a high level of process reliability,” adds Peter Eggert, Sales & Technology expert at acp. Thanks to integrated filter and extraction technology, the system also meets all requirements for safe and contamination-free operation.

The system is now available for both internal research projects and industrial cleaning and pretreatment jobs.

Further information on the SKZ research area of adhesive bonding and surface technology