Working together for quality and sustainability: Bavarian research project TeraFoam gets underway

With the “TeraFoam” project, the SKZ Plastics Center, together with Bavarian industry partners, is launching a technological revolution in plastics processing. The aim is to develop an innovative terahertz measurement system that records the bulk density and cell size of polymer foams during extrusion in real time. The new technology is intended to enable immediate optimization of the production process, thereby reducing waste and saving energy, time, and money.

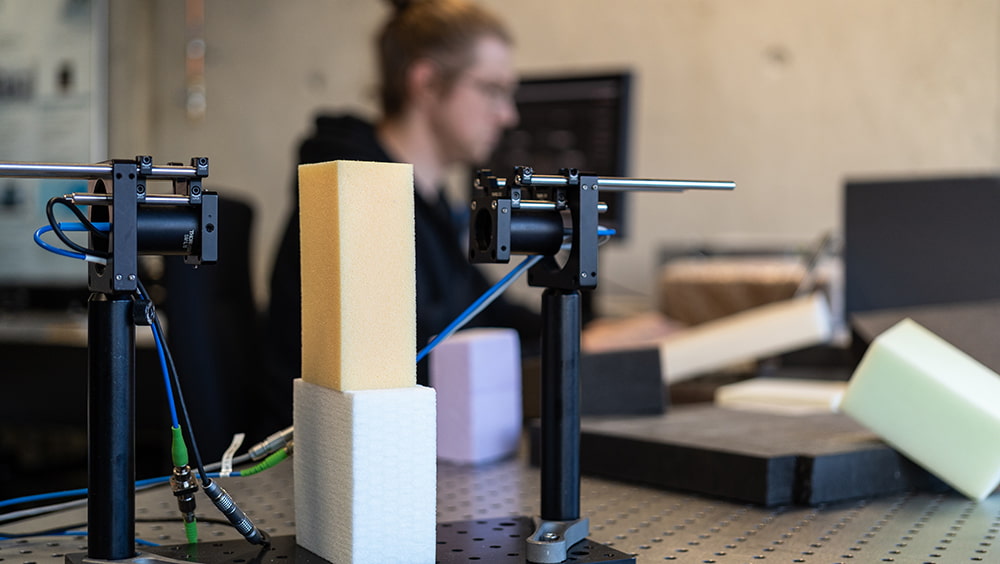

Untersuchung der Schaumparamater mit der THz-Technik in der Laborumgebung (Foto: Luca Hoffmannbeck, SKZ).

Research consortium develops inline measurement system for quality control in polymer foam extrusion

The joint project “TeraFoam” marks the start of a groundbreaking research initiative aimed at increasing resource efficiency in polymer foam extrusion. The aim is to develop an innovative terahertz measurement system that records the bulk density and cell size of foamed plastics inline and in real time. This allows production deviations to be detected and corrected immediately. This is a decisive step toward reducing waste, energy consumption, and CO₂ emissions.

The project is funded as part of the Bavarian Joint Research Program (BayVFP) and will run from July 2025 to June 2028. The consortium consists of esmo AG (special machine construction), Menlo Systems GmbH (photonics/measurement technology), and the SKZ Plastics Center. Together, the partners are developing a compact, high-precision measuring system based on terahertz technology that can be seamlessly integrated into industrial extrusion processes. Direct applicability in a real production environment will be demonstrated at the end of the project at an industrial foam manufacturer.

The expected effects are enormous: for a typical extrusion line alone, a greenhouse gas reduction potential of around 3,000 tons of CO₂ per year is forecast. In the long term, the technology opens up new possibilities for the digitalization of production and quality assurance in various industries, from insulation materials to elastomer foams.

“With TeraFoam, we are closing a key gap in polymer foam extrusion: for the first time, quality-relevant parameters such as bulk density and cell structure can be recorded inline and in real time. This not only enables significantly more stable process control, but also makes a measurable contribution to resource efficiency and climate protection,” says Marcel Mayr, Senior Scientist Non-Destructive Testing at SKZ.

The project team invites other foam manufacturers to actively participate by providing advice on integrating the measurement system into existing production processes, supplying foam samples, or performing measurements at their production facilities.

The consortium would like to thank the Bavarian State Ministry of Economic Affairs, Regional Development and Energy for its funding (FKZ: MW-2505-0004) as part of the Bavarian Joint Research Program (BayVFP), which is making this forward-looking project possible.

Further information on the SKZ Non-Destructive Testing Research Group