After five years, the Networked Materials Research Group is now an integral part of SKZ

From recipe development to material testing, the SKZ Plastics Center combines decades of expertise with state-of-the-art technology to create customized, sustainable, and high-performance materials for industry. For five years, SKZ has also been supporting research and development in the field of thermosetting plastics.

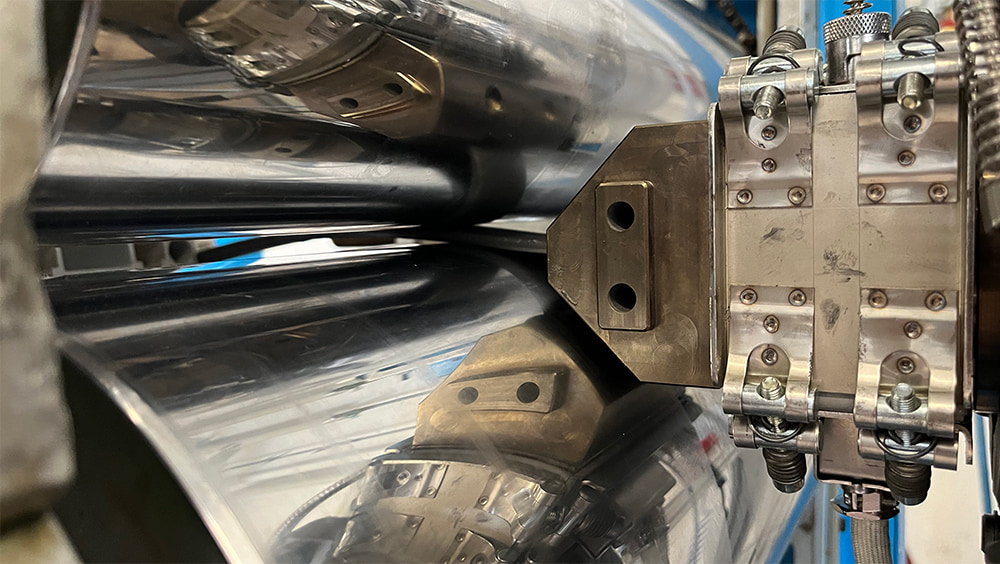

SKZ uses practical experience and state-of-the-art equipment to provide companies with optimal support—including in the field of thermosets. (Photo: Frederik Hellert, SKZ)

Würzburg institute offers comprehensive support in the field of thermosets

The SKZ offers companies comprehensive services in the field of thermosets and supports them in the development of innovative and sustainable material solutions. With decades of experience and close links between industry and research, SKZ is a reliable partner for challenging projects. The Würzburg-based plastics institute has been supporting industrial companies in optimization and development since 1961. Historically known for its expertise in thermoplastics, SKZ began building up deeper knowledge in the field of thermosets and silicones in 2020.

To this end, a new research group for cross-linked materials was established – with resounding success: Five years later, the group already has four employees and can look back on a series of successful projects. The core topics relating to thermoset materials have been established, and knowledge transfer to industry is continuously maintained.

This means that the still young group is ideally positioned to support industrial companies with a comprehensive range of services in the field of thermosets and to advance innovative projects. From initial consultation and material research to the development of individual formulations and the production of samples and prototypes, SKZ reliably accompanies its partners throughout the entire process. Thanks to state-of-the-art compounding technology, tailor-made solutions are created that are precisely tailored to the requirements of the respective application. It is also possible to synthesize proprietary resin systems on a laboratory scale, so that products can be adapted to specific requirements right from the first molecule. In addition, SKZ offers precise material data determination in accredited testing laboratories – for the highest quality and safety.

Currently in high demand are innovative mixtures that SKZ also develops or supports in their development: conductive systems, highly filled materials, or fiber-reinforced thermosets for extreme loads. Partners of the institute benefit not only from SKZ's comprehensive expertise, but also from access to the latest technologies, trends, and scientific findings. This combination of practical relevance and research makes it possible to optimally implement complex requirements such as mechanical properties, sustainability, or special functionalities.

“Thermosets are key materials for numerous industries. With our knowledge and the modern capabilities at SKZ, we help companies to realize innovative and sustainable solutions,” explains Thomas Zimmermann, Group Leader for Crosslinked Materials at SKZ.

As part of a strong network of industry, research, and education, SKZ promotes the exchange of know-how and accelerates innovation. In addition, SKZ supports companies in the development of resource-saving materials and recycling strategies in order to combine ecological and economic goals.

Further information on material development