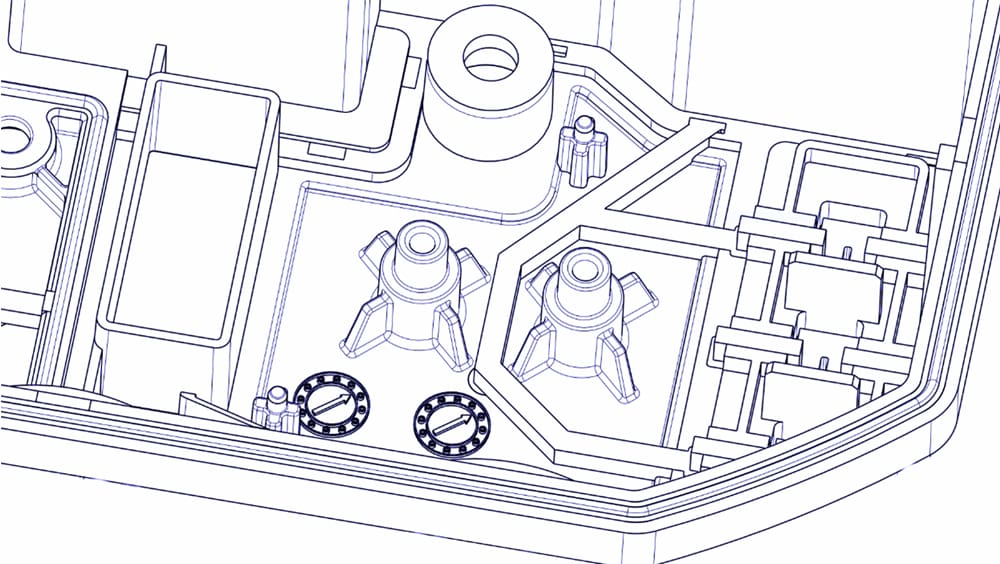

Optimal product design and tool technology for economically successful injection moulded parts

The economic success of a plastic product depends largely on the coordinated design of the article and the mould. The SKZ Plastics Centre is offering a new course that shows how article and mould design can be optimally coordinated from the outset – for greater quality, efficiency and cost-effectiveness in injection moulding production.

The new three-day course ‘Article Design and Tool Technology for Injection Moulded Parts’ will take place for the first time from 2 to 4 December at the SKZ Plastics Centre in Würzburg. (Source: SKZ)

Product design: Function meets economy

Product design determines the functional, aesthetic and technical properties of a component. The choice of materials, wall thicknesses, flow path lengths, rigidity and load scenarios are decisive parameters. Design errors often lead to quality defects, poor functionality, increased scrap rates or even product failure.

Tool technology as a success factor

Tool technology also plays a central role. It not only determines the shape, but also has a significant influence on process stability, product quality and cost-effectiveness. Aspects such as the positioning of the injection point, the design of the correct tool temperature control or compliance with the required tolerances and the planned cycle time have a significant influence on production efficiency and tool costs. Precise coordination between the article and the tool is therefore essential for stable and efficient series production.

New course offering at SKZ

Over three days, the SKZ Plastics Centre provides practical training on the most important design guidelines for injection-moulded parts and their impact on mould design. The course is aimed at designers, process managers and decision-makers who want to understand and optimise the entire development process – from the component to the finished injection mould. The classroom training will take place for the first time from 2 to 4 December 2025 at the SKZ Plastics Centre in Würzburg. Further dates will follow in 2026 at the headquarters in Würzburg and at the SKZ locations in Horb am Neckar, Halle (Saale) and Peine.

‘The potential offered by well-thought-out component and tool design is often still underestimated. However, enormous efficiency gains and cost savings can be achieved here,’ explains Robert Held, Group Leader for Injection Moulding and Additive Manufacturing Training at SKZ. ‘The increasing demands on optimal product and tool design prompted us to develop a new course that combines both areas of expertise.’

‘In injection moulding in particular, where very high quantities are usually produced, even small optimisations can have a major economic impact. Knowledge pays off particularly quickly here,’ adds Alexander Hefner, Deputy Head of Sales, Education and Research at SKZ.