Events

Find events

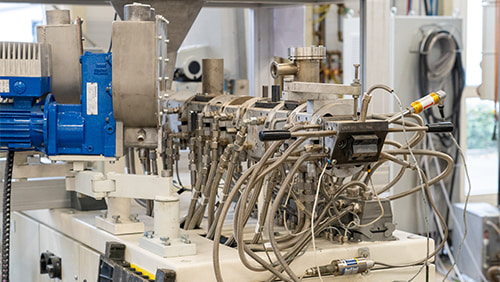

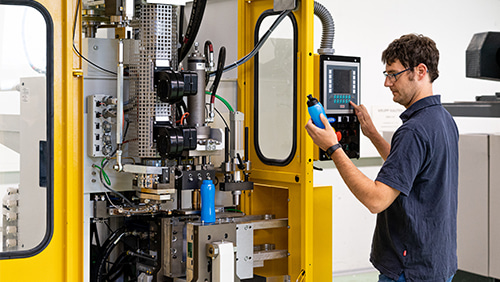

Inexpensive, flexible and sustainable: plastics knowledge with e-learning

Inexpensive, flexible and sustainable: plastics knowledge with e-learning

Learn

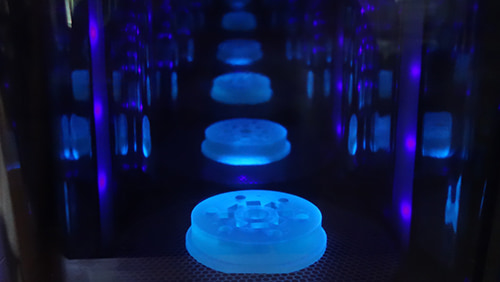

E-Learning.

Learning independent of space and time.

E-learning offers learners a flexible, cost-effective, and engaging way to acquire new knowledge and skills, making it an increasingly popular option for individuals and organizations. It offers the following advantages:

- Accessibility of knowledge

E-learning allows learners to access learning content from anywhere, at any time. This means that learners can learn at their own pace and on their own schedule. - Cost-effective

E-learning eliminates travel and accommodation costs, making it a cost-effective alternative to traditional classroom learning. - Flexibility

E-learning allows learners to customize their learning experience to their specific needs and preferences. - Higher learning impact

E-learning incorporates multimedia elements such as videos, animations, and interactive quizzes that increase learner engagement and improve retention. - Sustainability

E-learning can help reduce the environmental footprint by eliminating the need for travel and paper-based materials. - Individuality

SKZ also creates individual, company-specific e-learning content that companies can use on their internal learning platforms. Feel free to contact us about this.