Find projects

Additive manufacturing

Additive manufacturing (AM) has developed significantly in recent years and is establishing itself as another manufacturing process in the industrial environment. The developments show that additive manufacturing/3D printing continues to be an up-and-coming and rapidly evolving field that is used in almost all industries and offers a wide range of applications. The SKZ is helping to shape this development and is constantly expanding its offerings in the areas of services, research and training within a competence center for additive manufacturing, the Center for Additive Production (CAP) in Würzburg.

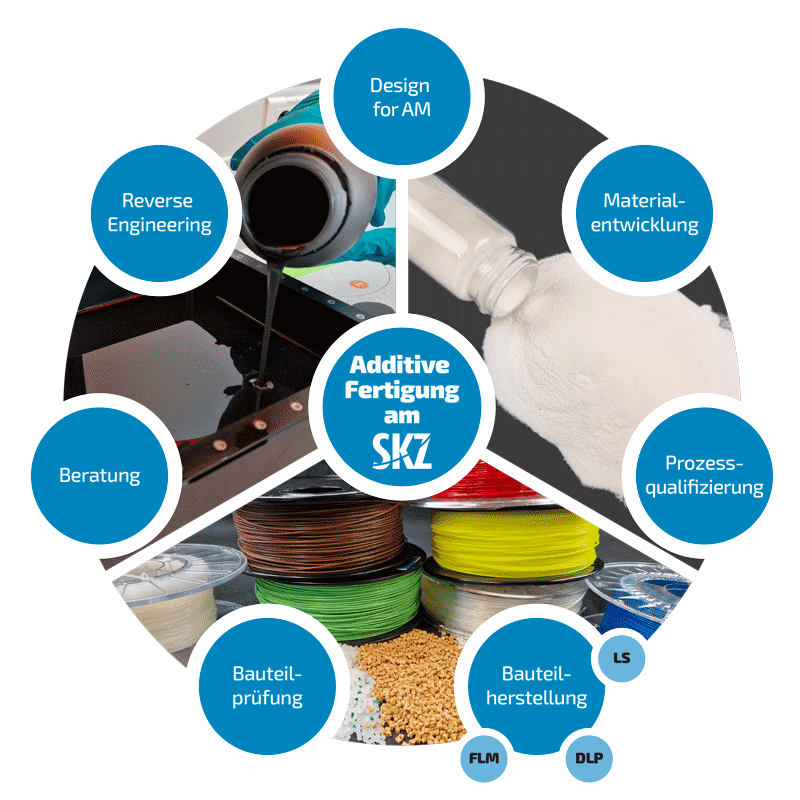

At the same time, the transfer of know-how to companies must keep pace with the rapid technical development. To this end, the range of services has been expanded and new training courses have been designed. This provides companies with a central, competent and independent point of contact. New materials, processes and applications are constantly entering the market. From consulting services, design for additive manufacturing, component production and testing to training courses and workshops, we support you in understanding and utilizing the complex aspects of additive manufacturing. The race for the profitable use of additive manufacturing technologies for series products is globally recognizable and Europe can and must fight vigorously and sustainably for a pioneering role.

Our services

How can we assist you?

To ensure that you achieve the desired result, we support you in the design of your components—from the initial idea to the finished part. Our experts are at your side to assist you with any questions you may have.

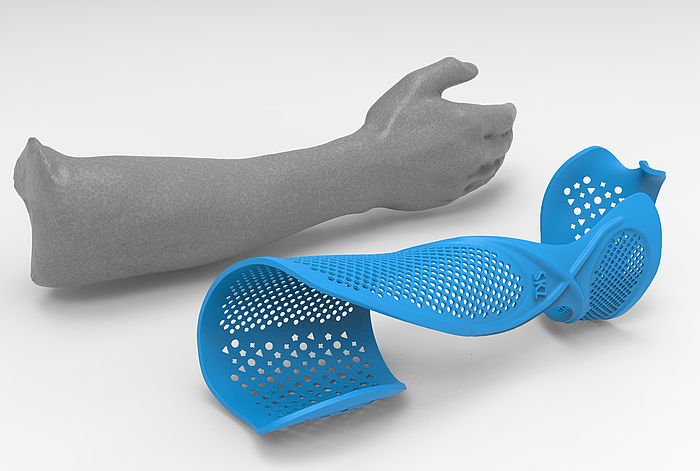

The SKZ has various 3D scanners at its disposal. Handheld scanners are used in the field of medical technology, among other areas, to design patient-specific implants, orthoses, or prostheses. Stationary 3D scans are mainly used for quality assurance. In combination with a wide range of CAD tools and 3D printers, the SKZ is ideally equipped to handle any application. The reverse engineering experts can digitize components and convert them into a CAD model in no time at all. This allows components to be developed and the efficiency of the development process to be increased, for example.

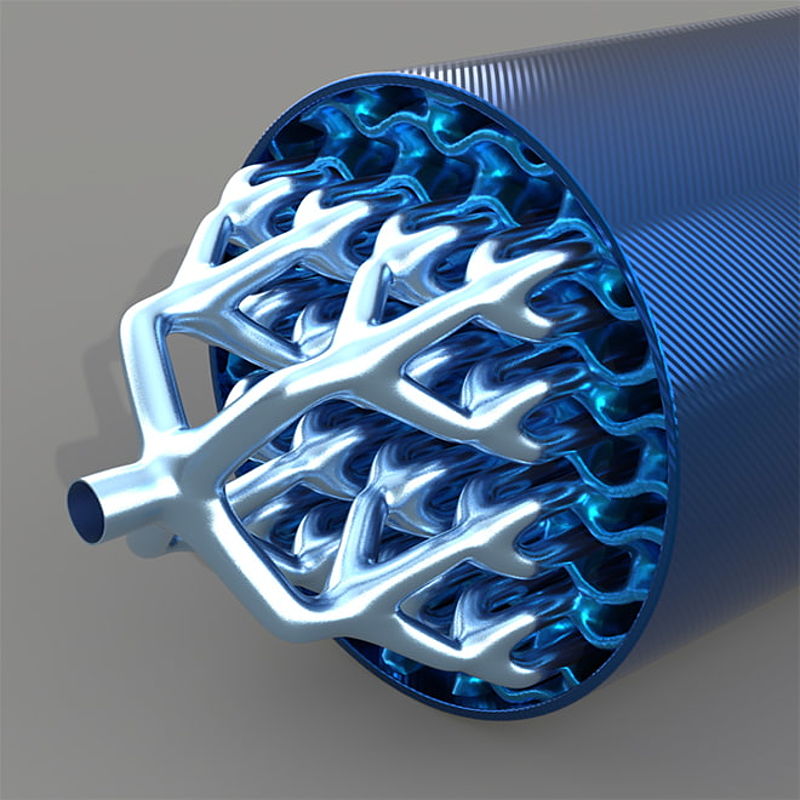

In order to exploit the full potential of additive manufacturing, the process-related restrictions and degrees of freedom must be incorporated into the design of components during the design phase. The right combination of modeling approach or strategy and software is essential. To ensure that you achieve the desired result, we take care of the design of your components or support you in the design of your components – from the initial idea to the finished component.

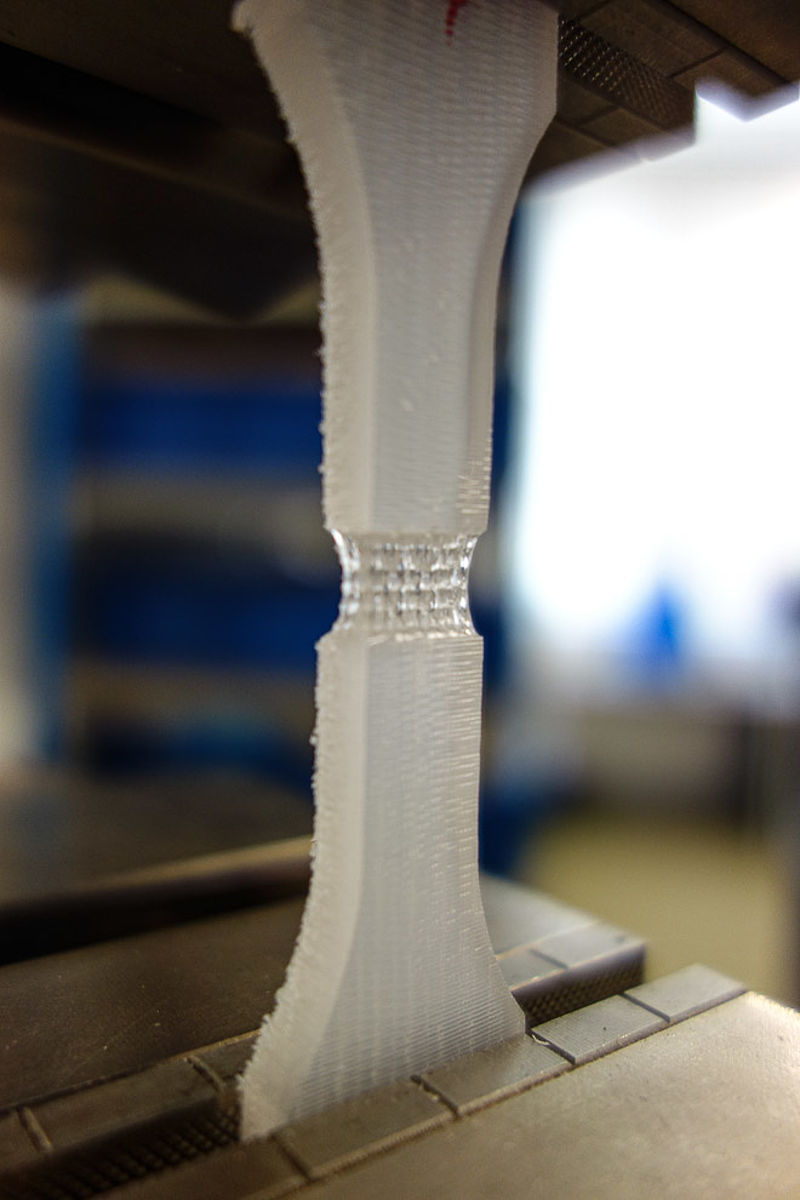

State-of-the-art technology is used to research the development of new materials in all forms (granulate, filament, resin, and powder). Fibers or other fillers and reinforcing materials can also be added. Various devices and systems are available at SKZ for the production of materials. During sampling, the behavior of materials is evaluated. When printing powders, resins, filaments, and granulates, the focus is on the following criteria: maximum mass throughput, geometric accuracy, shrinkage, warping and internal stresses, layer adhesion, behavior on overhangs, ability to bridge gaps, and adhesion to the build platform during production.

Process analysis in additive manufacturing refers to the examination and optimization of the entire printing process in order to improve the quality, efficiency, and repeatability of the manufactured parts. The team of experienced engineers and technicians will be happy to advise you on site and record the process-relevant and quality-determining parameters.

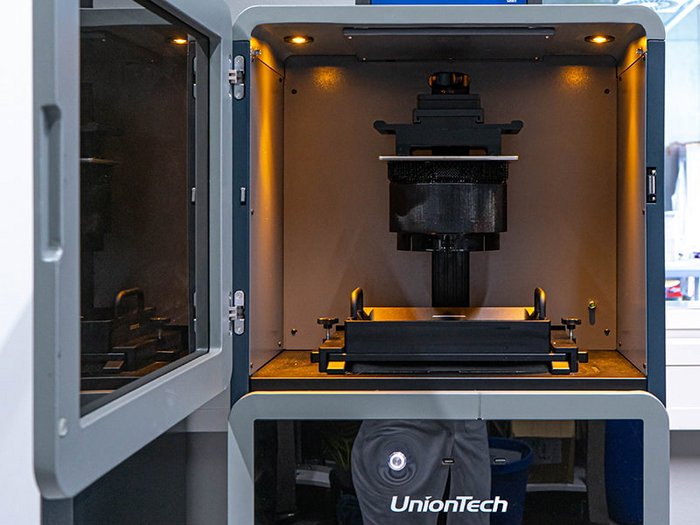

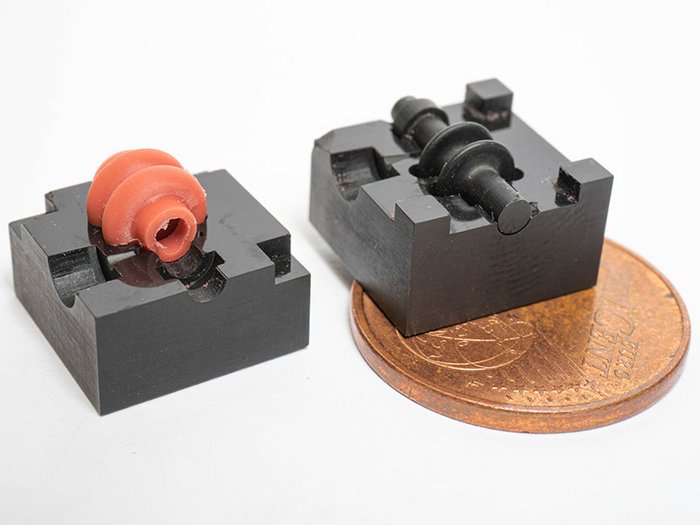

We offer component manufacturing on our commercial equipment and in-house facilities. Various printing processes such as powder bed, resin, and extrusion-based processes (granulate and filament) can be used, each with their own advantages and disadvantages in terms of the achievable properties (strength, stiffness, elongation at break, surface roughness, operating temperature, UV resistance, transparency, etc.) of the components. We also offer the option of manufacturing custom geometries that do not yet exist.

The production of test specimens in accordance with a wide range of standards and special test specimens is part of our numerous customer and R&D activities. We also offer the option of manufacturing custom geometries that do not yet exist. The additively manufactured components undergo state-of-the-art testing procedures to ensure the highest quality standards. With innovative technologies such as CT, optical measurement technology, and mechanical testing, we ensure dimensional accuracy, material integrity, and functionality for reliable results from prototype to series production.

We would be delighted to lead your project to success!

We look forward to working with you to achieve your manufacturing goals and bring your project ideas to life.

Our services at a glance

I have read the privacy policy.

State-of-the-art equipment for best results and products

A look inside our technical center. On more than 1,000 square meters, we offer you service at the highest level. Challenge us. Together we will find a solution for your problem.

Training in additive manufacturing & 3D printing

Practical courses for your future

Additive manufacturing and 3D printing are among the key technologies of modern production. Processes such as stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS) demonstrate the full range of these innovative technologies. The industry is developing rapidly—those who want to be successful in this field need up-to-date knowledge and practical training.

Our courses in 3D printing and additive manufacturing provide you with the necessary technical knowledge and practical skills to implement your own product ideas and take the next step in your career. Whether you are a technician, engineer, or career changer, our modular training concepts offer you exactly the additional qualifications that are currently in demand in additive manufacturing. We place particular emphasis on practical content that can be immediately applied in everyday working life. Whether you are a specialist looking to deepen your knowledge, a career changer wanting to learn the basics, or someone looking to advance your career by specializing in 3D printing, our training programs are flexible and tailored to your individual goals.

Your advantages:

- Practical courses in additive manufacturing and 3D printing

- Tailor-made training for specialists and career changers

- Up-to-date expertise on the latest developments

- Modular learning concepts for maximum flexibility

Shape your future with our practical trainings in 3D printing!

Get started now – expand your expertise, secure new career prospects, and become part of the future of production.

To our training program

What our customers say

"The R&D expertise in additive manufacturing at SKZ is extremely valuable to us. In our joint cooperation projects, we have repeatedly seen how well our expertise complements each other and has led to successful results. The open and trusting cooperation with the SKZ team has enabled us to identify synergies and drive forward innovative approaches. Their in-depth knowledge and proactive approach have not only led to efficient solutions, but also opened up new perspectives. We are grateful for the inspiring collaboration and look forward to tackling further groundbreaking projects together and further deepening our partnership."

Martin Efinger

CEO

Efinger Orthopädietechnik GmbH

"Our experience with SKZ in a joint research project was very positive. Communication with the staff was easy and quick. We were able to complete our project through excellent, solution-oriented teamwork—not least thanks to efficient project management. We also benefited from the expertise of SKZ's experts in the field of additive manufacturing. We would like to thank SKZ for the good and fruitful cooperation and can imagine further joint projects at any time."

Andre Neutzler

CEO

Ebalta Kunststoff GmbH

“Working with SKZ was an outstanding experience for us. The mutual commitment, expertise, and ability to creatively overcome challenges contributed to a successful project. The smooth communication and constant striving for excellence left a lasting impression. SKZ is undoubtedly a reliable partner whose professionalism and team spirit we value and recommend at all times.”

Thomas Teufel

Managing Partner

TEUFEL Prototypen GmbH

“Within the professional network, we work together to deliver innovative courses and training programs. I see the responsible teaching role at SKZ as a meaningful task with real value. Together, we are nurturing the skilled workers of tomorrow. Modern working methods and open communication between all participants support the success of the training.”

Alexander Käfer

"Working with SKZ has been extremely rewarding. Their knowledge and expertise in the field of additive manufacturing has helped us to advance our projects. From consulting to final production, they have always provided us with professional and reliable support. Thanks to their support, we were not only able to optimize our production processes, but also to implement innovative solutions. We were impressed by their dedicated and customer-oriented approach, and we look forward to continuing our successful collaboration in the future."

Dr. Raino Petričević

CTO and CEO

iNDTact GmbH