German Plastics Center (SKZ) develops IR technology to ensure 3D printing quality

In an ongoing research project, the German Plastics Center (SKZ) is developing a non-destructive inline inspection technique for 3D-printed components based on passive thermography. Reliable detection of specifically generated defect features is already possible.

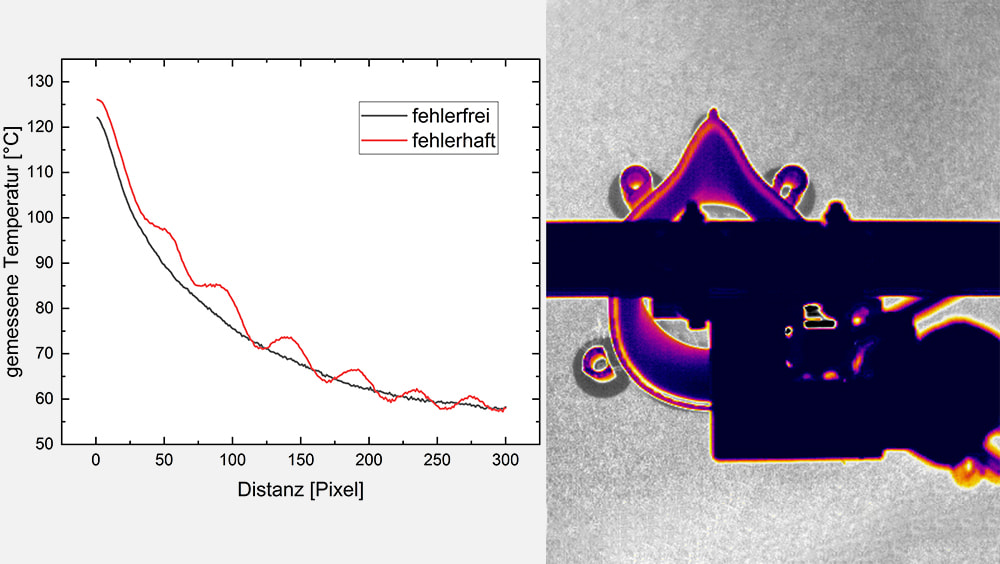

Temperature curve of a defect-free and a defective print area (left) and false-color image of a thermographic recording during FFF (right) (Photo: SKZ)

Inline thermography can be used to detect defects in the 3D printing process at an early stage

The growing demand for additively manufactured components also requires increasingly better quality control in production in order to optimize the efficiency of the sometimes complex production processes. Particularly in the case of large-scale printing, any errors that occur are often associated with high time losses. Continuous and quantifying process control is therefore indispensable in the future. In the widely used process of Fused Filament Fabrication (FFF), thermography shows great potential due to the combination of the measurement of the filament temperature and the large-scale imaging of the printed object. Therefore, SKZ is developing an inline measurement technique based on passive thermography in the research group "Non-destructive Testing", which enables a permanent control of the components manufactured by means of FFF.

Detecting the defect while it is still hot

The tests showed that specifically generated defect features can be reliably detected in the recorded temperature curves. Classic defect features such as under-extrusion or poor layer adhesion can be clearly distinguished from the reference layers by deviations in the cooling curves. The video sequences were recorded using cameras kindly provided by Optris GmbH. The generated measurement data can be classified into defect and defect-free regions using classical evaluation algorithms and thus form the basis of a data set for training a neural network. This enables a classification in ok and not-ok objects. Interested companies can participate in the project free of charge and test their products on the developed measurement system or validate their suitability for use in the system.

Project 21677 N is funded by the German Federal Ministry of Economics and Climate Protection (BMWK) through the German Federation of Industrial Research Associations (AiF) as part of the program for the promotion of joint industrial research (IGF) and places particular emphasis on the needs of SMEs.